WN600 has two main filter elements, glass fiber filter element and composite filter element. Both have their own advantages and disadvantages. For specific differences, please consult customer service.

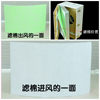

The picture is a glass fiber filter element. The effect is also a glass fiber filter element. The chemical fiber filter element has a paper frame and is slightly thinner in size. The two filter elements are used alternately. When using glass fiber filter element, use one piece of filter cotton. When using composite filter element, use three pieces of filter cotton (if activated carbon is added, use one piece of filter cotton, because the frame of the composite filter element is thin.

Large machine chemical fiber filter element: 695mm long, 445mm wide, 55mm thick, and the fold density is lower than that of glass fiber filter element, but the air resistance is much lower than that of glass fiber filter element, so the air volume is much larger, the paper frame and the outer frame thickness are about 55mm (the outer frame is thinner than glass fiber element)

The following description mainly refers to glass fiber filter element:

Picture description:“Efficiency is 99.99%”, refers to the filtering efficiency of the filter element itself, which does not attenuate (except for damage), but the resistance of the filter element will gradually increase as the dust accumulates.The filtration efficiency after installation is also related to the body sealing condition. Generally, there is no need to pursue it deliberately, because even 99% efficiency is enough for the family..“0 particles at home”, refers to the timely replacement of filter elements with excessive wind resistance, and there is no impact of backflow outdoors, Hanwang haze table measurement, due to backflow outdoors, the actual effect of some houses is not 0, and there is actually no need to pursue 0. The service life is half a year to two years, which refers to the average service life of heavy pollution in winter in North China and light pollution in other seasons, as long as the initial filter cotton in our store must be added for pre-filtration.Generally, the filter element needs to be replaced not because the resistance is too great, but because it is contaminated and the odor cannot be removed. We are exploring ways to solve the odor problem caused by pollution.

For general chemical fiber filter elements (such as PP filter elements, PP+PET composite filter elements, etc.), because they adopt the principle of electrostatic adsorption to collect dust, the electrostatic charge will gradually be lost, so the filtration efficiency will gradually decrease.When used as fresh air, because it has always filtered dirty air, if the haze is severe, the efficiency will generally drop seriously in about one month (in winter, when the haze is severe, it usually takes half a year to a year).

Large machine glass fiber filter element size : 695mm long, 445mm wide, 55mm fold height, 69mm thick outer frame, about 360% fold!One fold is 44.5 cm long and 5.5 cm wide. You can calculate how large my filter element is. Don’t ask what the use is if the area is large!

Small machine glass fiber filter element size: length and width 484mm*484mm, fold height and fold density are the same as those of large machine glass fiber filter element

Fiberglass fiber cannot be cut (aluminum frame, fully sealed, and both sides are protected by plastic spray iron mesh)

Fiberglass Hepa Efficiency is about 99.99% H13 level aluminum frame double-sided protective mesh glue-filled seal area 8.5 square meters